Understanding Procurement Methodology

Procurement methodology is all about the tactics, systems and 'methods' used by procurement teams. 'Procurement' is more approach the strategic side of purchasing - the systematic approach you use to acquire goods, services, and works for your organisation. There are lots of methods and in this article we aim to cover as many as the key ones as possible - keeping it brief and simple.

If you have any questions - contact us - hello@thorntonandlowe.com

The most common procurement methods include:

- Open tendering

- Restricted tendering

- Request for quotation

- Direct procurement

- Framework agreements or mini competitions or quotes via already established approved suppliers lists

Each method has its own advantages and is suited to specific situations. Open tendering, for instance, promotes competition and transparency - often worth it for a strategically important and higher value contract. While direct procurement may be more appropriate for urgent or low-value purchases.

When selecting a procurement method, you should consider:

- Value and complexity of the purchase

- Urgency of requirement

- Market conditions

- Legal and regulatory requirements

The procurement process typically involves several stages:

- Identifying needs

- Planning and budgeting

- Defining specifications

- Selecting suppliers

- Evaluating bids

- Awarding contracts

- Managing and monitoring performance

Effective procurement methodology aims to achieve value for money, fairness, and efficiency. It ensures you obtain the right goods and services at the right time, price, and quality. And that's all we ever want!

By understanding and applying some of these procurement methods and best practices, you can optimise your organisation's purchasing activities and contribute to its overall success.

Types of Procurement Methods

Procurement methods play a crucial role in how organisations acquire goods and services. Each approach offers distinct advantages and suits different circumstances.

Open Tendering

Open tendering invites all interested suppliers to submit bids for a specific project or contract. This method promotes transparency and competition, potentially leading to cost savings. You'll find it commonly used in public sector procurement.

Advantages:

- Wide participation

- Increased competition

- Transparency

Disadvantages:

- Time-consuming process

- Higher administrative costs

Open tendering often involves public advertisements and formal bid submissions. It's best suited for large-scale projects or when you're seeking a diverse range of potential suppliers.

Restricted Tendering

In restricted tendering, you prequalify potential suppliers before inviting them to submit bids. This method balances competition with efficiency by limiting participation to capable vendors.

Key features:

- Two-stage process

- Prequalification of suppliers

- Limited number of bidders

Restricted tendering is useful when you need specialised goods or services. It helps ensure that only qualified suppliers participate, saving time and resources in the evaluation process.

Two-Stage Tendering

Two-stage tendering separates the technical and financial aspects of procurement. In the first stage, you evaluate suppliers' technical proposals without considering price. The second stage focuses on pricing from shortlisted vendors.

Benefits:

- Allows refinement of requirements

- Emphasises technical quality

- Reduces risk of unsuitable bids

This method is particularly effective for complex projects where specifications may need adjustment based on suppliers' input.

Selective Tendering

Selective tendering involves inviting a specific group of pre-approved suppliers to bid. You maintain a list of qualified vendors and choose from this pool for each procurement.

Advantages:

- Faster than open tendering

- Ensures supplier quality

- Builds long-term relationships

Drawbacks:

- Limited competition

- Potential for favouritism

This method works well when you have ongoing procurement needs and want to maintain a reliable supplier base.

Competitive Bidding

Competitive bidding encourages suppliers to offer their best terms by pitting them against each other. You specify your requirements and invite multiple vendors to submit bids.

Key aspects:

- Clear specifications

- Multiple bidders

- Evaluation based on price and quality

This method often results in cost savings but requires careful management to ensure quality isn't compromised for the sake of lower prices.

Single-Source Procurement

Single-source procurement involves selecting a specific supplier without competition. You might use this method when there's only one viable vendor or when you need to maintain consistency in products or services.

Pros:

- Streamlined process

- Consistency in supply

- Potential for better terms through long-term relationships

Cons:

- Lack of competition

- Potential for higher prices

- Risk of over-reliance on one supplier

Use single-source procurement judiciously, as it can lead to complacency and missed opportunities for better deals.

Request for Quotations (RFQ)

An RFQ is a straightforward method where you ask suppliers to provide prices for specific goods or services. It's typically used for standardised products or when price is the primary factor.

- Define requirements

- Send RFQ to potential suppliers

- Evaluate responses based on price and terms

- Select the best offer

This method is quick and efficient for simple, low-value purchases.

Request for Proposals (RFP)

RFPs are more comprehensive than RFQs, focusing on both price and quality. You provide detailed specifications and evaluation criteria, inviting suppliers to propose solutions.

Key elements of an RFP:

- Project scope

- Technical requirements

- Evaluation criteria

- Timeline

RFPs are ideal for complex projects where you're open to different approaches and want to leverage suppliers' expertise.

E-Procurement

E-procurement uses digital platforms to manage the procurement process. It streamlines operations, reduces paperwork, and enhances transparency.

Benefits:

- Increased efficiency

- Real-time tracking

- Cost savings

- Improved supplier relationships

Challenges:

- Initial implementation costs

- Need for staff training

- Cybersecurity concerns

E-procurement is becoming increasingly popular, offering a modern approach to managing your supply chain and vendor relationships.

Speak to an expert!

Contact usStages of the Procurement Process

The procurement process involves several key stages that organisations must navigate to acquire goods and services efficiently.

Identification of Needs

Procurement begins with recognising and defining organisational requirements. You'll need to conduct a thorough analysis of your business needs, involving stakeholders from various departments. This stage is critical for setting clear objectives and specifications.

Create a detailed requirements document outlining:

- Quantity and quality of goods or services needed

- Delivery timeframes

- Budget constraints

- Technical specifications

- Performance expectations

Engage with end-users to gather insights and ensure all requirements are captured accurately. This step forms the foundation for the entire procurement process, so take care to be comprehensive and precise.

Sourcing and Market Research

Once needs are identified, you'll move on to researching potential suppliers and market conditions. This stage involves:

- Identifying potential suppliers

- Analysing market trends and pricing

- Assessing supply chain risks

- Evaluating new technologies or innovations

Utilise various methods to gather information:

- Online research

- Industry reports

- Supplier databases

- Networking events

- Trade shows

This research helps you understand the supplier landscape and informs your strategy for the subsequent stages of the procurement process.

Supplier Selection and Evaluation

With market research complete, you'll begin evaluating and selecting potential suppliers. This stage typically involves:

- Developing selection criteria

- Issuing Requests for Proposal (RFP) or Requests for Quotation (RFQ)

- Reviewing and scoring supplier responses

- Conducting supplier due diligence

Create a scorecard to assess suppliers based on factors such as:

- Price competitiveness

- Quality of goods or services

- Delivery capabilities

- Financial stability

- Compliance with regulations

- Sustainability practices

Shortlist the most promising suppliers for further evaluation and potential negotiations.

Contract Negotiations

After selecting preferred suppliers, you'll enter into contract negotiations. This stage is crucial for establishing mutually beneficial agreements. Key aspects to focus on include:

- Pricing structures and payment terms

- Service level agreements (SLAs)

- Delivery schedules

- Quality standards

- Warranty and support provisions

- Intellectual property rights

- Liability and indemnification clauses

Aim for win-win outcomes that foster long-term relationships. Be prepared to compromise on less critical points while standing firm on essential requirements. Involve legal experts to ensure all contractual terms are clear and protect your organisation's interests.

Management of Supplier Relationships

Once contracts are in place, you'll need to focus on managing supplier relationships. This ongoing process involves:

- Regular performance reviews

- Monitoring key performance indicators (KPIs)

- Addressing issues or disputes promptly

- Identifying opportunities for improvement

- Collaborating on innovation and cost-reduction initiatives

Establish clear communication channels and schedule periodic meetings with key suppliers. Develop a supplier scorecard to track performance consistently. Be proactive in addressing any concerns and work collaboratively to resolve issues.

Procurement Execution and Delivery

The final stage involves executing the procurement plan and managing the delivery of goods or services. Your responsibilities include:

- Issuing purchase orders

- Coordinating logistics and delivery

- Conducting quality inspections

- Managing inventory

- Processing invoices and payments

- Addressing any discrepancies or issues

Implement robust systems to track orders, deliveries, and payments. Ensure proper documentation is maintained throughout the process. Regularly review and optimise your procurement execution to improve efficiency and reduce costs.

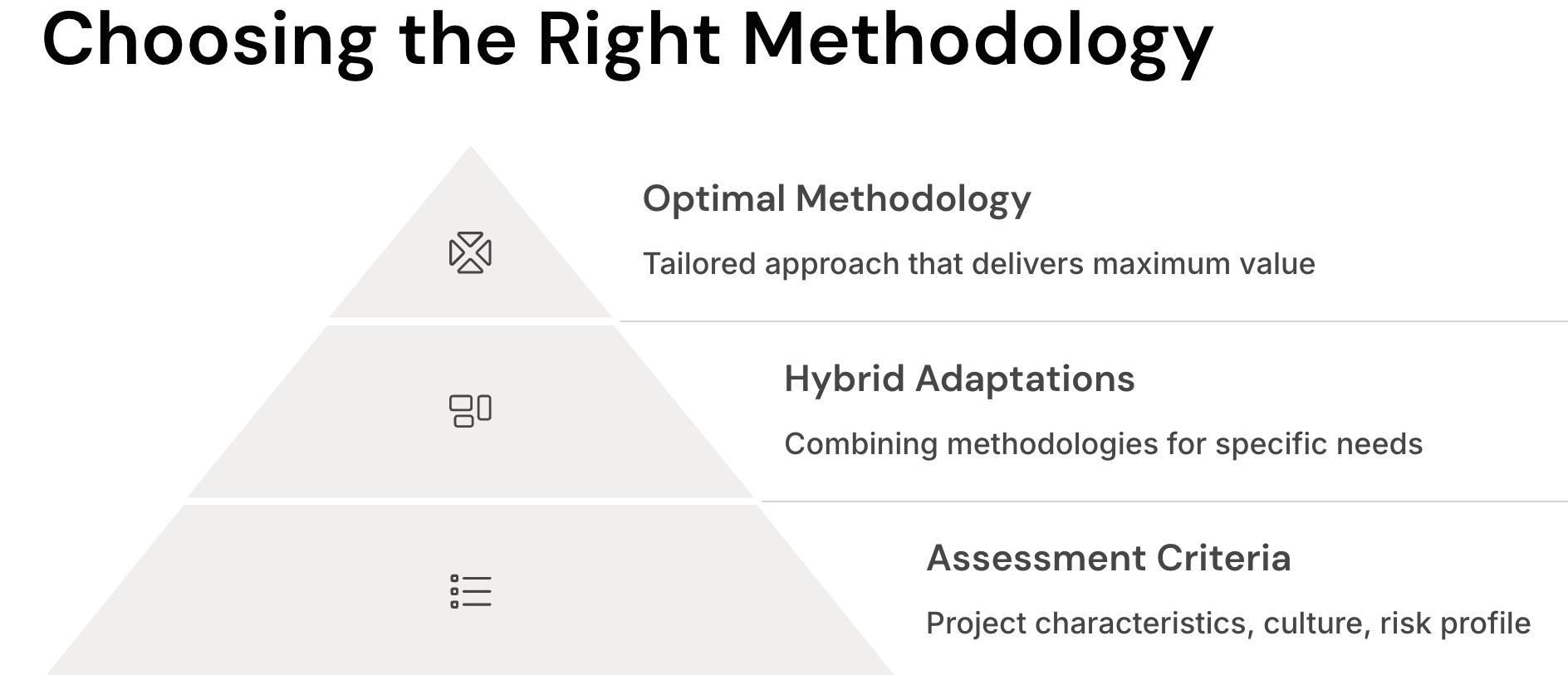

Strategic Procurement Planning

Strategic procurement planning aligns purchasing activities with organisational goals to maximise value and minimise risks. It involves developing targeted strategies, managing potential issues, identifying cost-saving opportunities, and ensuring quality standards are met.

Developing a Procurement Strategy

Your procurement strategy should outline specific objectives and approaches for acquiring goods and services. Start by analysing your organisation's needs and market conditions. Identify key suppliers and evaluate their capabilities. Set clear goals for cost reduction, quality improvement, and risk mitigation.

Consider different procurement methods such as competitive bidding, direct negotiation, or framework agreements. Each approach has unique advantages depending on the product or service being procured.

Create a timeline for implementation and establish key performance indicators (KPIs) to measure success. Regular reviews and adjustments will ensure your strategy remains effective as business needs evolve.

Risk Management in Procurement

Effective risk management is crucial in procurement. Identify potential risks such as supply chain disruptions, price fluctuations, or quality issues. Assess the likelihood and impact of each risk to prioritise your mitigation efforts.

Develop contingency plans for high-priority risks. This may include:

- Diversifying your supplier base

- Implementing robust supplier evaluation processes

- Establishing buffer stock for critical items

- Negotiating flexible contracts to accommodate market changes

Regular supplier audits and performance monitoring can help you spot potential issues early. Consider using risk assessment tools and technologies to streamline this process.

Cost Savings Initiatives

Implementing cost savings initiatives is a key aspect of strategic procurement. Start by analysing your current spending patterns to identify areas for improvement. Consider the following approaches:

- Consolidate purchases to leverage economies of scale

- Negotiate volume discounts with key suppliers

- Implement e-procurement systems to reduce administrative costs

- Explore alternative materials or specifications without compromising quality

- Conduct regular market analysis to ensure competitive pricing

Collaboration with internal stakeholders is crucial. Work closely with finance, operations, and other departments to align cost-saving efforts with overall business objectives.

Quality Standards and Specifications

Maintaining high-quality standards is essential for successful procurement. Develop clear and detailed specifications for all goods and services you procure. These should outline:

- Required performance characteristics

- Acceptable quality levels

- Testing and inspection procedures

- Compliance with relevant industry standards

Involve technical experts and end-users in developing specifications to ensure they meet actual needs. Regularly review and update specifications to reflect changes in technology or business requirements.

Implement a robust supplier quality management programme. This may include supplier audits, sample testing, and performance monitoring. Establish clear quality metrics and incorporate them into supplier contracts and evaluation processes.

Legal and Ethical Considerations

Procurement processes must adhere to strict legal and ethical standards to ensure fairness, transparency, and value for money. These principles protect both the procuring entity and suppliers whilst promoting public trust.

Transparency Requirements

You must maintain open and clear communication throughout the procurement process. Publish tender notices and award decisions publicly. Document all steps, decisions, and interactions thoroughly.

Provide equal access to information for all potential bidders. Clearly state evaluation criteria and weightings upfront. Offer debriefings to unsuccessful bidders upon request.

Use e-procurement systems to enhance transparency and reduce opportunities for corruption. These platforms create audit trails and allow for easier oversight.

Consider publishing contract details and spend data, subject to commercial confidentiality. This openness demonstrates accountability and allows for public scrutiny.

Promoting Fair Competition

Develop specifications that are not overly restrictive or biased towards particular suppliers. Focus on performance requirements rather than specific brands or solutions.

Allow sufficient time for bid preparation to encourage wider participation. Set reasonable qualification criteria that don't unfairly exclude smaller or newer firms.

Rotate suppliers for repeat purchases where appropriate. This prevents over-reliance on a single vendor and encourages market competition.

Implement conflict of interest policies. Require staff involved in procurement to disclose any potential conflicts and recuse themselves when necessary.

Addressing Non-Competitive Procurement

Use competitive processes whenever possible. However, recognise that non-competitive procurement may be necessary in certain situations.

Establish clear guidelines for when single-source or limited tendering is permissible. Common justifications include urgency, specialised expertise, or follow-on work.

Implement additional controls for non-competitive procurement. Require higher-level approvals and more detailed justification documentation.

Conduct market research to ensure fair pricing even in non-competitive situations. Consider using techniques like benchmarking or should-cost analysis.

Regularly review and audit non-competitive procurements to identify potential abuses or areas for improvement.

Innovations in Procurement

Procurement practices are evolving rapidly with new technologies and approaches reshaping traditional methods. These innovations aim to increase efficiency, reduce costs, and promote sustainability in procurement processes.

Advantages and Disadvantages of E-Procurement

E-procurement systems streamline purchasing processes through digital platforms. They offer faster transactions, broader supplier access, and improved spend visibility. You can automate routine tasks, reducing errors and freeing up staff time for strategic work.

However, e-procurement requires significant upfront investment in technology and training. Some suppliers may struggle to adapt, potentially limiting your options. Security concerns also exist, as digital systems can be vulnerable to cyber attacks.

Despite these challenges, e-procurement often leads to cost savings through better pricing and reduced administrative overhead. It also enables data-driven decision-making by providing detailed analytics on spending patterns and supplier performance.

The Role of Technology in Procurement

Technology is transforming procurement beyond just e-procurement systems. Artificial intelligence (AI) and machine learning are enhancing forecasting accuracy and automating supplier selection. You can use these tools to analyse vast amounts of data, identifying trends and opportunities for optimisation.

Blockchain technology is improving supply chain transparency and traceability. It allows you to track goods from source to delivery, reducing fraud and ensuring compliance with regulations and ethical standards.

3D printing is revolutionising prototyping and small-scale production, potentially reshaping your supplier relationships. Cloud-based systems enable real-time collaboration with suppliers and internal stakeholders, improving communication and decision-making.

Sustainable Procurement Practices

Sustainability is increasingly vital in procurement strategies. You can implement practices that consider environmental and social impacts alongside economic factors. This might involve prioritising suppliers with strong environmental credentials or those committed to fair labour practices.

Circular economy principles are gaining traction, encouraging you to consider product lifecycle and recyclability in purchasing decisions. You might explore leasing or service-based models instead of outright purchases to reduce waste and resource consumption.

We will often work with clients to research, test and recommend the right tech solution for their procurement needs - whether is supplier due dil or managing complex procurement projects.

Challenges and Complexities in Procurement

Procurement faces significant hurdles that can impact organisational success. Complex projects, cost management, and supplier evaluation present ongoing difficulties for procurement teams.

Dealing with Complex Projects

Complex procurement projects require meticulous planning and execution. You'll often encounter intricate specifications, multiple stakeholders, and tight deadlines. To navigate these challenges:

• Break down large projects into manageable phases • Establish clear communication channels with all parties involved • Implement robust project management tools and techniques

Risk mitigation becomes crucial in complex projects. You must identify potential issues early and develop contingency plans. Regular progress reviews and adaptability are key to keeping complex procurements on track.

Ensuring Cost-Effectiveness

Balancing cost savings with quality and value is a persistent challenge. You need to:

• Conduct thorough market research to understand pricing trends

• Negotiate effectively with suppliers

• Explore alternative sourcing options

Consider implementing e-procurement systems to streamline processes and reduce administrative costs. Volume discounts and long-term contracts can offer significant savings, but you must weigh these against the risks of over-reliance on single suppliers.

Performance Evaluation of Suppliers

Assessing supplier performance is vital for maintaining quality and reliability. You should:

• Establish clear KPIs for supplier evaluation

• Regularly monitor and review supplier performance

• Provide constructive feedback to suppliers

Use data analytics to track supplier metrics objectively. This approach helps identify areas for improvement and informs decisions about contract renewals or terminations. Building strong supplier relationships can lead to better performance, but you must balance this with maintaining competitive tension in your supply base.

Evaluating Procurement Outcomes

Effective evaluation of procurement outcomes ensures projects deliver value and meet organisational objectives. Regular assessment throughout the process helps identify areas for improvement and maintain alignment with business needs.

Project Management and Oversight

You should establish clear project management practices to oversee procurement outcomes. Define key performance indicators (KPIs) aligned with your business goals. These may include cost savings, delivery timelines, and quality metrics.

Implement a robust project management system to track progress and milestones. This allows you to quickly identify and address any deviations from the plan.

Regular project reviews and status meetings keep stakeholders informed and encourage collaboration. Use these opportunities to assess performance against KPIs and make data-driven decisions.

Consider using project management software to centralise information and streamline communication. This promotes transparency and simplifies reporting.

Audit and Compliance Monitoring

Conduct regular audits to ensure compliance with procurement policies and regulations. Develop a checklist of key compliance areas to review, including:

- Adherence to tender processes

- Proper documentation

- Conflict of interest declarations

- Fairness in supplier selection

Implement a risk-based approach to auditing, focusing more attention on high-value or complex procurements. This helps allocate resources efficiently whilst maintaining oversight.

Use audit findings to refine your procurement processes and provide targeted training to staff. This continuous improvement cycle enhances compliance and reduces risks over time.

Consider automating compliance checks where possible to increase efficiency and reduce human error. This could include using software to flag potential issues or inconsistencies in procurement data. It can be such a time consuming area - especially if not set up right from the start! Which it rarely is. Fix it when you have a 100 suppliers, rather than 1,000. Or speak to us and let us help!